Umatshini wokuRisayiklishwa kwePlastiki

BuzaNgathi

I-Polytime Machinery Co., Ltd. lishishini lokurisayikilisha kunye nokukhuselwa kwendalo esingqongileyo elidibanisa imveliso kunye ne-R&D, ligxile ekwenziweni kokuvasa imveliso yeplastiki kunye nezixhobo zomgca wepelletizing. Ukusukela ekusekweni kwayo kwiminyaka eli-18, inkampani iphumeze ngempumelelo iiprojekthi ezingaphezulu kwama-50 zokurisayikilisha zeplastiki kumazwe angaphezu kwama-30 kwihlabathi jikelele. Inkampani yethu ine-IS09001, ISO14000, CE kunye nezatifikethi ze-UL, sijolise ekubekweni kwemveliso ephezulu, kwaye sizame ukuphuhlisa kunye nabathengi. Injongo yenkampani kukugcina amandla kunye nokunciphisa ukukhutshwa kunye nokukhusela umhlaba wethu wekhaya.

IZINIKEZELO

Uyilo lomgca wePelletizing wezinto ezithambileyo ezikrwada zahlukile kuyilo lwezinto ezilukhuni ekrwada

IZISOMBULULO ZEMATERIAL Ethambileyo ENGAHLAZWAYO NJENGEZANTSI

I-LDPE /LLDPE /HDPE FILM/PP FILM/PP ELUKIWEYO ISIGABA

IMATERIAL EKHIQIWEYO NJENGEZANTSI

HDPE/ LDPE/ PP/ ABS/ PC/ PS/ PA/ PA66

Umgca we-pelletizing wemathiriyeli ekrwada ethambileyo uya kuxhotyiswa nge-agglomerator ngokwesiqhelo, esetyenziselwa ukukrazula ifilimu ibe ngamaqhekeza amancinci emva koko uyicinezele ibe yibhola ukunyusa ukusebenza kakuhle kokutyisa imathiriyeli ekrwada emgqomeni.

Indawo eqaqambileyo(umgca omnye weentlobo ezi-2 ezahlukeneyo zemathiriyeli ekrwada)

I-POLYTIME-M inokubonelela ngoyilo lwezixhobo ezithambileyo neziqinileyo ngomgca omnye wemveliso (Phantsi kweemeko ezithile, umzekelo umthengi unokwamkela umahluko wemveliso) 76%

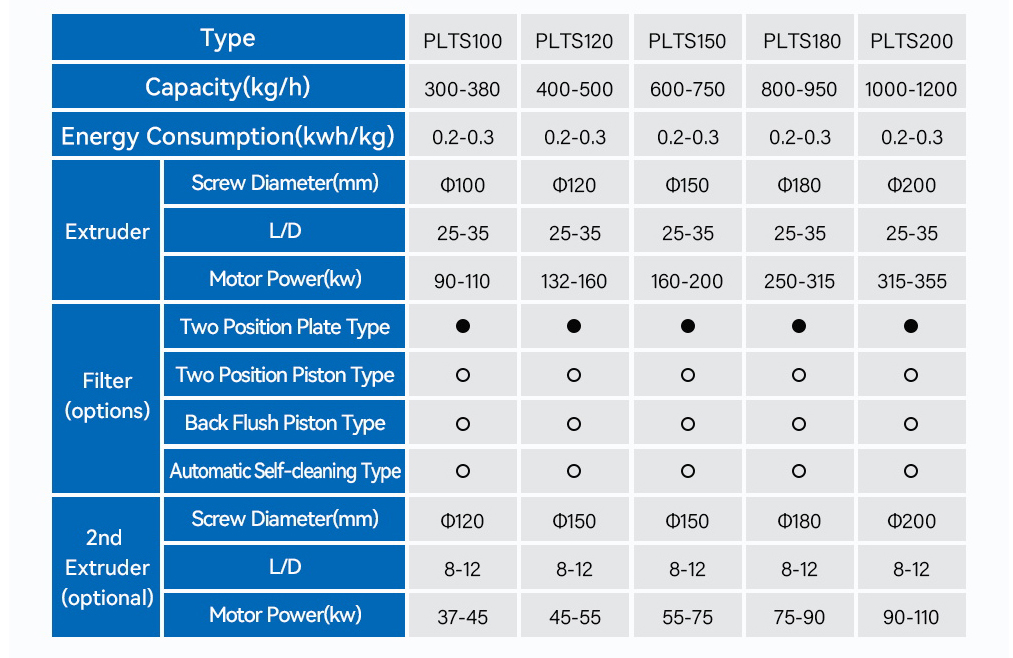

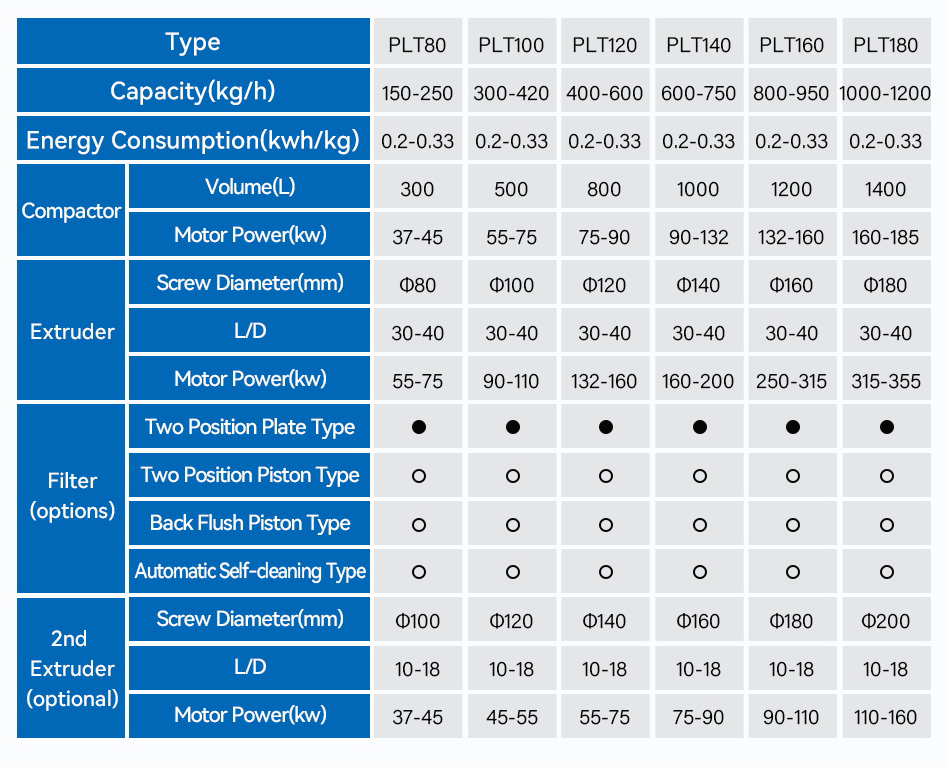

-Iparamitha yoBugcisa -

Umgca wePlastiki oqinileyo weGranulation

Soft Plastic Granulation Line

Inqanaba elinye okanye inqanaba eliphindwe kabini?

Umgca wenqanaba eliphindwe kabini legranulation liqhele ukusetyenziselwa imathiriyeli ekrwada ethi emva kokuhlanjwa, inokuzisa izihlandlo ezi-2 zokususa igasi ukukhupha ukufuma, kwakhona amaxesha ama-2 okucoca ukwenza i-pelletizing icoceke ngakumbi.

Inqanaba elinye lomgca wepelletizing usetyenziselwa imathiriyeli ekrwada ecocekileyo efana nenkunkuma yoshishino, kubandakanywa nokuphela kokwenziwa kweephakheji zeplastiki.

- Iimbonakalo -

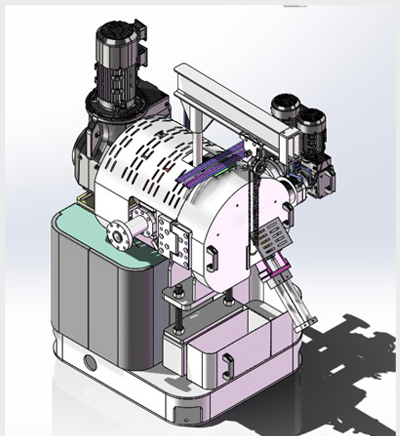

I-CONICAL TWIN-SCREW EXTRUDER

■ I-Servo motor, i-15% yokunciphisa ukusetyenziswa kwamandla

■ PLC inkqubo yokusebenza ekrelekrele, ulawulo olukude

■ Umsebenzi ongundoqo wokuqala, iindleko zokufunda eziphantsi

■ Umsebenzi wokufudumeza kwangaphambili ukuphucula ukusebenza kwemveliso

■ Ukondla inkqubo yokulawula umthamo, ukuthelekisa izixhobo ezahlukeneyo zeMFI

■ 1500kg/h MAX umthamo wemveliso

■ Ukungcangcazela okuphantsi kunye nengxolo ephantsi

Uhlobo lweSakhiwo soMda weMveliso

Iqonga elinye- Lifanelekile

ngezinto ezimdaka kancinci

Iqonga eliphindwe kabini-Ifanelekile

ngezinto ezimdaka ezimdaka kakhulu

Ukusika Uhlobo

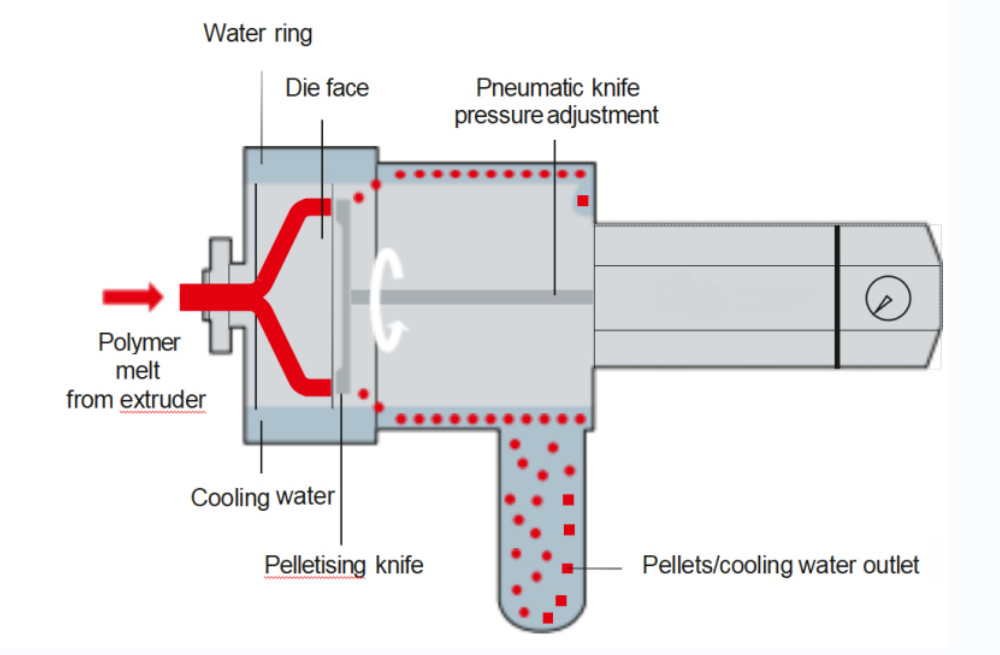

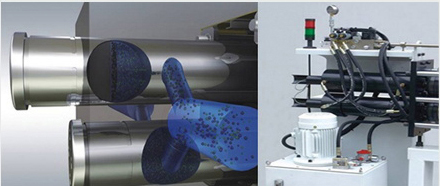

● Ukusika umsesane wamanzi (Ifanelekile i-HDPE, i-LDPE, i-PP)

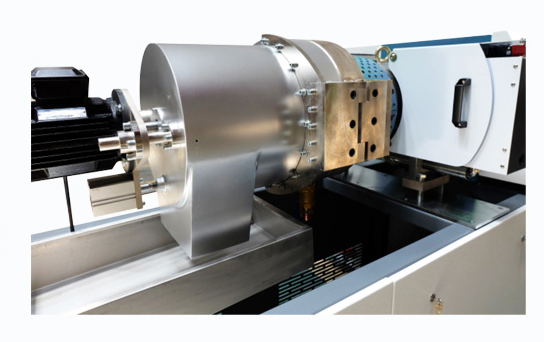

Iinkqubo ze-Polytime-M ezishushu zobuso be-pelitisi ziye zadlula kwelinye inqanaba lophuhliso. Ugxininiso bekusoloko kukuphatha ngokuthe ngqo kunye nokugcinwa lula.

■ Intshukumo engenakulondolozwa kunye negudileyo yomatshini woxinzelelo lwentloko yemela

■Knife head driveshaft ene-direct drive

■ Ukuchaneka okugqwesileyo kokusika kudityaniswe nesetingi yoxinzelelo lokusika lwepneumatic oluzenzekelayo

■ Iimela zePelletizer kunye nobuso obufayo zinobomi obude benkonzo

■ Ukusika ngaphantsi kwamanzi (i-PET iyacetyiswa)

■ Ukusika imigca (Ifanelekile kwiimathiriyeli ezahlukeneyo)

Umtshintshi wesikrini

● I-hydraulic yendawo ephindwe kabini

Iindleko eziphantsi, ukusebenza okulula, kodwa indawo yokucoca ayinkulu

● Ikholamu ephindwe kabini yokutshintsha isikrini se-hydraulic

Iindleko ziphezulu kunebhodi yokutshintshiselana kwesikrini esiphindwe kabini, ukusebenza kancinci okuntsokothileyo, kodwa indawo enkulu yokucoca, inceda ukuthoba ukuphindaphindeka kokubuyisela umnatha wokucoca.

● Isihluzi selaser esizenzekelayo

Ukucoca okuphambili, kufakwa ngokubanzi kwinqanaba lokuqala lomgca we-pelleitizng ukususa ungcoliseko olukhulu, kodwa utyalo-mali luphezulu.

Isikrini esilungiselelwe ukususwa kwamanzi e-pellet kunye nesiphumo sokuzicoca kunye nekhatriji yokucoca ngokulula.

I-Pellet centrifuge yokuphucula ukomisa ukusebenza nge-Direct Drive ubuchwepheshe

Umlimi kunye nokukhuselwa kwengxolo okudityanisiweyo kwi-pellet yezindlu zeCentrifuge - amacandelo asezantsi omlambo

Isigqubuthelo sendlu esongwayo kwi-pellet centrifuge yokucoca ngokulula xa utshintsha imibala kunye nokugcinwa ngqo phambili

Isikrini esitsha sokwahlula amanzi epellet

Imibuzo kuwe phambi kokuba sinikele

■Yintoni imateria!?PP okanye iPE,ithambile okanye iqinile?

■Ingaba impahla ekrwada icocekile okanye imdaka?

■Ingaba imveliso ekrwada emva kokuhlanjwa?

■Yintoni iMFI yemathiriyeli ekrwada?

■Ingaba imathiriyeli ekrwada inayo nayiphi na ioli nepeyinti?

■Ingaba imathiriyeli ekrwada iqulethe nayiphi na isinyithi?

■Yintoni ukufuma kweepellets zokugqibela ozifunayo?

■Yintoni usetyenziso lwemveliso yokugqibela?

■ Ngaba uyafuna kwakhona intambo yokudibanisa iipilisi?

■Unganceda wabelane nathi ngemifanekiso yemathiriyeli ekrwada ukuze siyiqonde ngcono.

Inzuzo yobuGcisa

■ Itekhnoloji ye-Direct Drive enoyilo olungashukumiyo

■ Ukuthambisa ubomi bonke kwishaft yokuqhuba

■ Ubomi benkonzo yemela yepelletiser ende enkosi kwijiyometri ekhethekileyo yokusika kunye noxinzelelo lwemela oluzenzekelayo

■ Ukongamela umsebenzi we-pelletiser ngokuzenzekela ngophawu lwe-alam kunye nokuvalwa okuzenzekelayo kwimeko yokungasebenzi kakuhle.

Iinzuzo zoqoqosho

■ Ilungele ukusetyenziswa phantse nazo zonke ii-extruders eziqhelekileyo

● Iqondo eliphezulu lokuthembeka komsebenzi kunye nokwehliswa okubonakalayo kweendleko zolondolozo

● Ukutshintsha kwemela ye-pelletiser elula nekhawulezayo ngaphandle komsebenzi wohlengahlengiso konga ixesha

■ Ukulungelelaniswa okuguquguqukayo kwesixhobo ezantsi komsinga we-pelletizer

■ Ukuthotywa kweendleko zamanzi okupholisa ngenxa yenkqubo esebenzayo yokupholisa iipellet